Wound Filament Plastic Bushing

Product Characteristics

| Basic Type | High Load / High Temperature |

| Material | Wound Fiber Glass Based Polymer Plastic with PTFE |

| Types | Plain Type Sleeve / Flange Bushing / Washer / Custom Design |

| Product Code | DOB-WFB Series |

| Diameter: | from 2 to 550 mm,and length from 2 to 375 mm |

| Static Load: | 240 ~ 485 Mpa |

| Density: | 1.9 |

| Working Temperature: | ±180°C |

DALON Filament Wound Plastic Bushing Material Series

Standard Filament Wound Plastic Plain Bushing List

DALON also offer custom size, please contact for quotation

Specification Calculate

Volume

Weight

Standard B-21 Properties

| GENERAL | UNIT | VALUE |

| Density | g/cm³ | 1.9 |

| Static Load | Mpa | 240 |

| Dynamic Load | Mpa | 160 |

| Max Speed | m/s | 0.2 |

| Max PV | MPa*m/s | 2.0 |

| Coefficient of friction | - | 0.03 ~0.12 |

| Working Temperature | °C | ±180 |

| Short-time work Temp. | °C | -196~230 |

| Radial compressive strength | Mpa | 500 |

| Hardness | HRM | 95 |

| 25~150°C Linear thermal expansion factor | um/m°C | 13×10-6 |

Plastic Bushing

Introduction to DALON Filament Wound Plastic Bushing

- Introducing the pinnacle of advanced bushing technology, DALON's filament wound plastic bushing sets new standards in durability, performance, and efficiency. Our plastic bushings are meticulously engineered, combining the resilience of fiber glass with the unmatched smoothness of PTFE, all encapsulated within a robust composite structure.

- Innovative Construction for Unrivaled Performance:

- - At the heart of our plastic bushing lies the inner lining, a sophisticated blend where PTFE fibers intertwine with special high-strength fibers to create a sliding layer that boasts exceptional lubricity and wear resistance. This innovative design ensures seamless motion, reducing friction and enhancing the longevity of both the bushing and the counterpart surfaces. Encasing this sliding paradise is the outer lining, crafted from polymer fiber reinforced with high-temperature and high-strength epoxy resin. This load-bearing layer is not just a shell but a fortress, offering unparalleled support and resistance to environmental challenges, including high temperatures and mechanical stresses.

- Versatile Offerings for Diverse Applications:

- - DALON's wound fiber glass composite bushings are not limited to standard shapes. Our catalog spans bushings, plates, discs, and specialized forms, designed to cater to a wide array of industrial needs. Whether your application demands unique geometries or specific performance criteria, DALON is equipped to deliver solutions that fit seamlessly into your operations.

- Self-Lubricating and Maintenance-Free:

- - Our composite plastic bushing emerges as a beacon of innovation in the realm of non-metal self-lubricating shaft sleeves. The continuous winding of PTFE and high-strength fiber creates an inner sliding layer that eradicates the need for external lubrication. Backed by a polymer fiber reinforced epoxy resin layer, our bushings assure high-temperature resilience and strength, setting a benchmark for maintenance-free operation.

- In essence, DALON's filament wound plastic bushing represents the future of friction management technology. It embodies a perfect harmony between advanced materials and cutting-edge manufacturing, offering a solution that is not only sustainable but also elevates the operational efficiency of a wide spectrum of applications. Choose DALON for a bushing experience that transcends traditional limitations, ensuring your machinery operates at its peak, uninterrupted and efficient.

Chemical Resistance of Filament Wound Plastic Bushing

Resistant: + ; Not Resistant : -

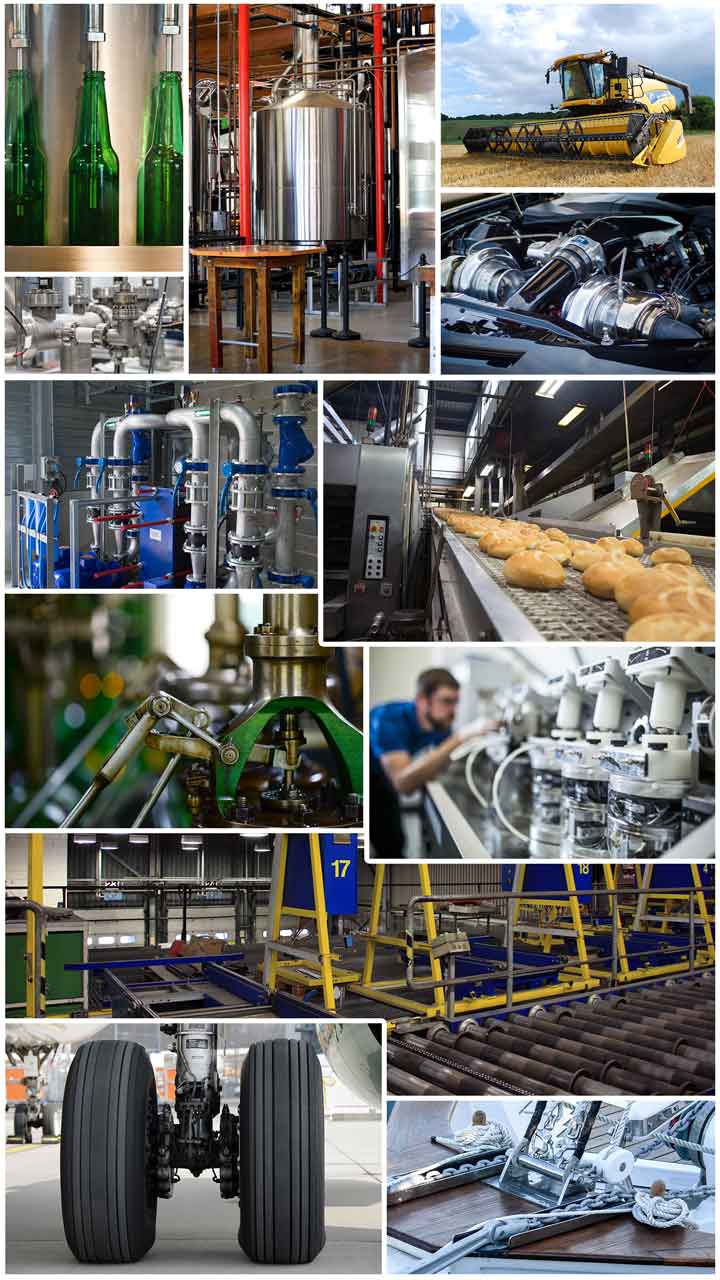

Application Examples:

- DALON Plastic Bushing Advantage:

- Wound filament plastic bushings offer a unique combination of advantages that make them highly sought after in various applications across industries. Here’s a brief overview of their key benefits:

- Self-Lubricating:

- - The integration of PTFE fibers provides exceptional lubrication, eliminating the need for external lubricants and reducing maintenance requirements.

- Corrosion Resistance:

- - Unlike metal bearings, filament wound plastic bushings are resistant to corrosion from chemicals, water, and other corrosive environments, making them ideal for marine and chemical processing applications.

- High Load Capacity:

- - The reinforced epoxy resin and fiber glass structure offers a high load-bearing capacity, comparable to metal bearings but with a lower weight.

- Wear Resistance:

- - The unique material composition, including high-strength fibers, ensures excellent wear resistance, prolonging the service life of both the bushing and the mating components.

- Low Coefficient of Friction:

- - These bushings operate with a lower coefficient of friction compared to metal bearings, enhancing efficiency and reducing energy consumption.

- Noise Dampening:

- - The composite material naturally dampens vibration and noise, contributing to quieter operation, which is particularly beneficial in automotive and industrial applications.

- Environmentally Friendly:

- - With no need for oil or grease lubrication, filament wound plastic bushings offer an environmentally friendly alternative, reducing the potential for pollution.

- Filament wound plastic bushings, like those offered by DALON, represent a significant advancement in bearing technology, providing a compelling alternative to traditional metal sliding plain bearings. These bushings find their applications across a broad spectrum of industries due to their unique construction and material properties. Here's a detailed look at their applications and advantages:

Used in steering columns, pedal assemblies, door hinges, and suspension systems where durability and noise reduction are crucial.

Applied in control systems, actuators, and landing gear assemblies, where high strength-to-weight ratio and corrosion resistance are essential.

Ideal for use in conveyors, assembly lines, and heavy-load equipment, offering low maintenance and high performance in dirty or abrasive environments.

Used in tractors, harvesters, and irrigation systems, where exposure to dust, soil, and chemicals demands robust and durable bearings.

Suitable for rudder assemblies, winches, and pulley systems, benefiting from corrosion resistance in salty and humid environments.

Applied in wind turbines and solar panel tracking systems, where they withstand variable loads and harsh weather conditions.

Utilized in processing and packaging machinery, where non-toxic, clean, and maintenance-free components are required.

Used in medical equipment and devices, where precision, cleanliness, and reliability are paramount.

- DALON's filament wound plastic bushings embody the evolution of bearing technology, offering a superior, maintenance-free alternative to traditional metal bearings across a wide array of applications. Their advanced material properties and construction provide significant operational benefits, making them a preferred choice for engineers and designers seeking to enhance the performance and reliability of their equipment.