DOB-1 Self Lubricating Multilayer Composite Bushing

Product Characteristics

| Manufacturer | DALON |

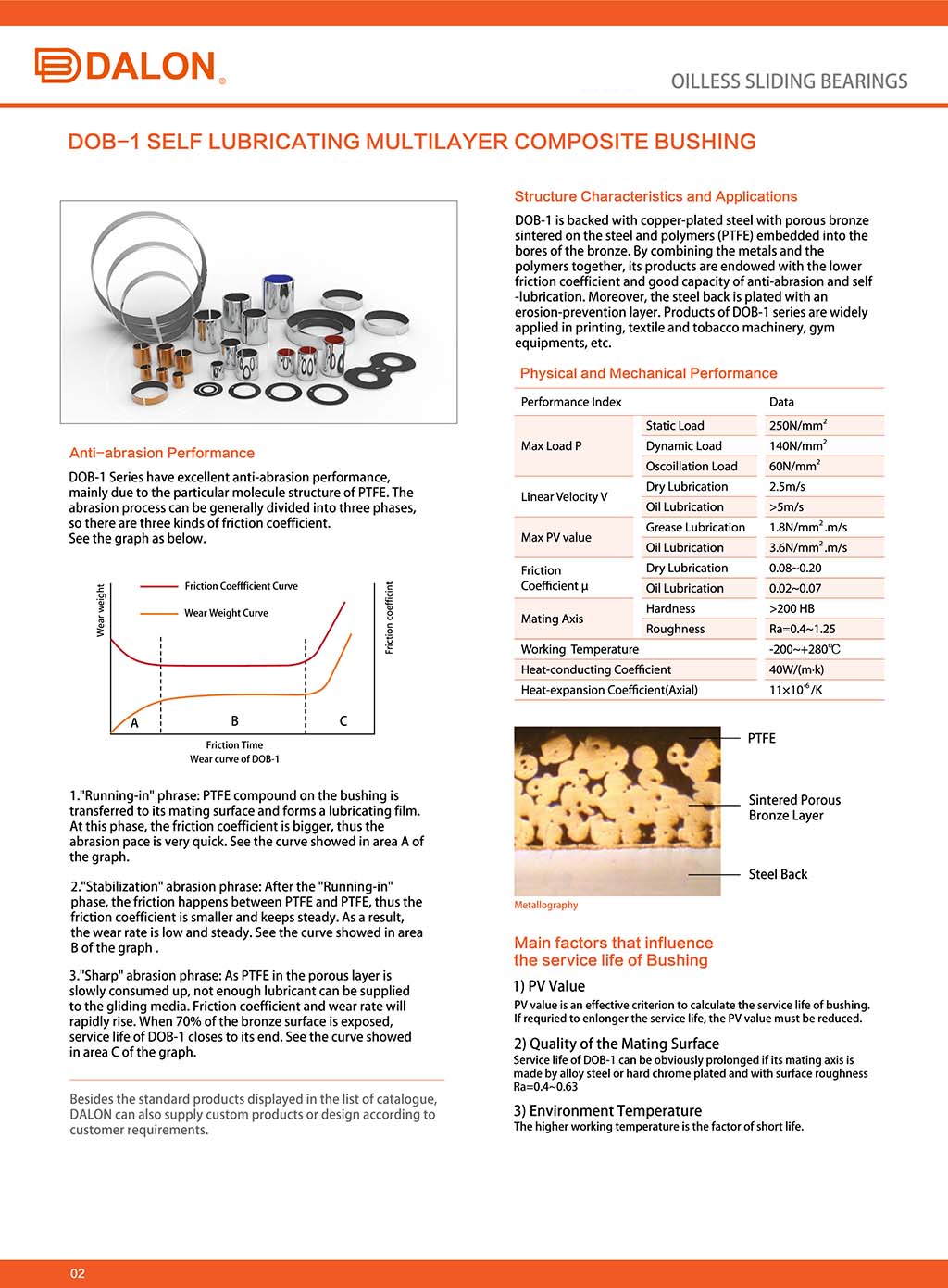

| Material | Multilayer Composite Material: Steel Back + Bronze Layer + PTFE |

| Types | Plain Type Split Sleeve / Flange Bushing / Washers |

| Product Code | DOB-1 |

| Lubricating: | Oilless Self-Lubricating |

| PV Value Limit | 1.8 Static load N/mm².m/s |

| Max Line Speed V: | 2.5 Dry Friction m/s |

| Load Capacity: | 250 Static load N/mm² |

| Friction coef u: | 0.08 ~0.20 Dry |

Specification Calculate

Volume

Weight

DOB-1 Self Lubricating Multilayer Composite Bushing

Introducing our advanced oilless sliding bushing

- the self-lubricating, multilayer composite solution engineered to optimize the performance and durability of your machinery with minimal maintenance. Our cutting-edge oilless bushings are designed to meet the rigorous demands of a wide array of industries, including automotive, aerospace, industrial machinery, and more, offering a high-performance alternative to traditional lubricated bearings.

- Innovative Multilayer Design:

- - At the core of our oilless sliding bushing is a sophisticated multilayer structure that includes: Base Layer: A high-strength steel backing that provides structural integrity and support. Intermediate Layer: A sintered bronze matrix that enhances load-bearing capabilities and thermal conductivity. Sliding Layer: Made of specially formulated solid lubricants, this layer delivers exceptional self-lubricating properties, allowing for smooth operation under varying conditions without the need for additional lubrication.

- Enhanced Performance and Reliability:

- - Our oilless sliding bushings are crafted to withstand harsh environments and operate under high loads and temperatures without compromising performance. The self-lubricating feature ensures a low coefficient of friction, significantly reducing wear and extending the life of both the bushing and the equipment. This design not only enhances efficiency but also contributes to energy savings and reduced operational costs.

- Versatile and Eco-Friendly:

- - Perfect for applications where environmental concerns or access issues make liquid lubricants impractical, our oilless bushings provide a clean, maintenance-free solution that helps keep machinery running smoothly and sustainably. The versatility of these bushings allows them to be used in a variety of settings, from heavy industrial equipment to delicate precision instruments, ensuring optimal function without the ecological footprint of traditional lubricants.

- Customizable Solutions:

- - Understanding that each application has unique requirements, we offer customization options for our oilless sliding bushings to ensure the perfect fit and performance for your specific needs. Whether it's adjusting dimensions, modifying the material composition, or tailoring the sliding layer, we are committed to providing a tailored solution that meets and exceeds your expectations.

- Choose our oilless sliding bushing for a reliable, high-performance, and sustainable solution in your machinery applications. Trust in our technology to deliver unparalleled durability and efficiency, keeping your operations smooth and maintenance-free.

Application Examples:

- Detailed Application Range of Oilless Bushings:

- Oilless bushings, with their unique self-lubricating features, are utilized across various sectors where durability, efficiency, and low maintenance are essential. Here are eight primary application areas:

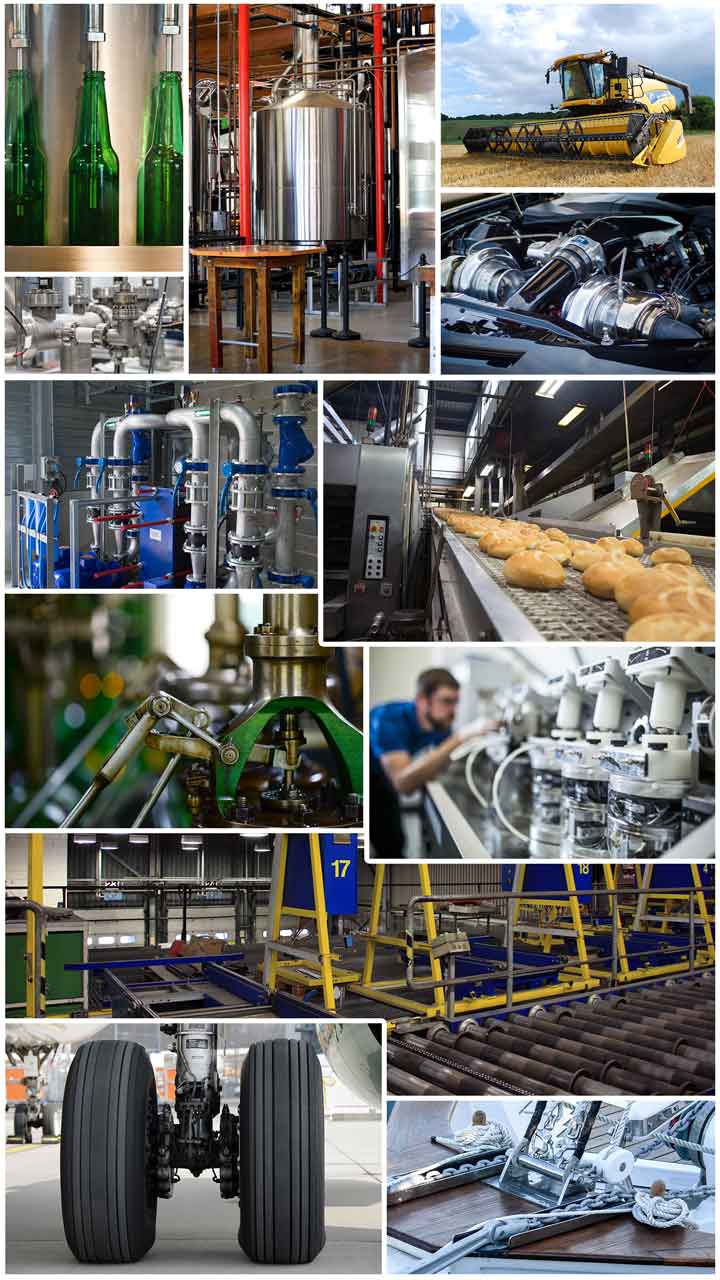

- Automotive Industry:

- - Oilless bushings are used in vehicle chassis, steering assemblies, pedal systems, and door hinge components. They provide durability and smooth operation in the demanding automotive environment, where reliable performance without regular maintenance is crucial.

- Aerospace:

- - These bushings are used in aircraft control mechanisms, landing gear, and cabin seating systems. Their ability to perform under high loads and varying temperatures makes them ideal for aerospace applications where safety and performance are paramount.

- Industrial Machinery:

- - Oilless bushings are applied in various machines such as presses, hydraulic lifts, and conveyor systems. They can withstand heavy loads and harsh conditions found in industrial settings, reducing downtime and maintenance costs.

- Agricultural Equipment:

- - In tractors, combines, and harvesters, oilless bushings ensure smooth operation and resist dirt and grit, common in farming environments, thus extending the equipment's service life.

- Construction Machinery:

- - These bushings are used in construction equipment like excavators, loaders, and cranes, where they provide high load-bearing capacity and resistance to dust and debris.

- Food Processing Equipment:

- - Oilless bushings are suitable for applications within the food processing industry due to their cleanliness and maintenance-free characteristics, ensuring no lubricant contamination occurs in food production lines.

- Advantages of DALON Oilless Sliding Bushings:

- Oilless bushings offer several significant advantages that make them suitable for these diverse applications:

- Maintenance-Free:

- Being self-lubricating, they do not require additional greasing or oiling, reducing maintenance efforts and costs.

- High Load Capacity:

- Oilless bushings can bear significant loads, making them suitable for heavy-duty applications in industrial and construction machinery.

- Corrosion Resistance:

- Many oilless bushings are made from materials that are resistant to corrosion, making them ideal for use in harsh environments.

- High Durability:

- These bushings are designed to endure wear and tear, offering a long service life under challenging operational conditions.

- Environmentally Friendly:

- The lack of need for additional lubrication reduces the environmental impact associated with the disposal and leakage of lubricants.

- Operational in Extreme Conditions:

- They perform well under high temperatures and pressures, which is crucial in automotive and aerospace applications.

- Clean Operation:

- Since there’s no grease or oil, they are ideal for use in clean-room environments or food processing applications where cleanliness is a priority.

- Custom Made:

- Available in various sizes and materials, oilless bushings can be customized to meet specific requirements, enhancing their applicability across multiple sectors.

- The combination of these advantages with their extensive application range highlights the versatility and efficacy of oilless bushings in meeting the demanding needs of modern machinery and equipment across a multitude of industries.

- Make the choice with DALON MACHINERY. Trust us to provide reliable, efficient, and innovative oilless sliding bushings that propel your business forward. Choose quality, choose sustainability, choose us! Visit our website or contact us today to learn more about how our oilless sliding bushings can benefit your operations.