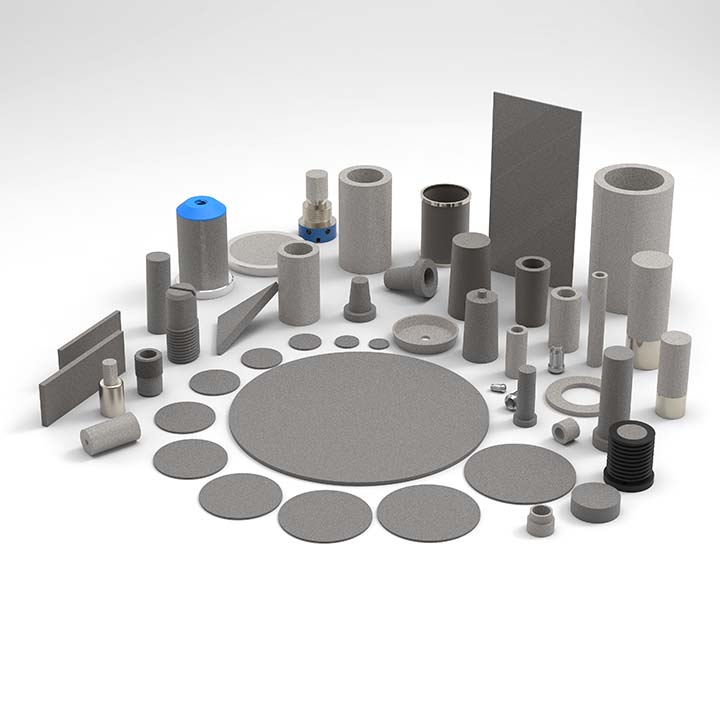

Sintered Stainless Steel Filter

Product Characteristics

| Manufacturer | DALON |

| Material | POROUS STAINLESS STEEL 316L |

| Product Code | SSF |

| Pore Pitch: | from 5 µm to 100 µm |

| Diameter: | from 2 to 250 mm,and length from 2 to 500 mm |

| Porosity: | 25 up to 45% |

| Density: | from 5.5 to 6.5 |

| Traction: | resistance 3-9kg/mm2 |

| Dilatation: | coefficient 16x10-6 |

| Working Temp: | 800°C -MAX |

Specifications

Standard Geometries

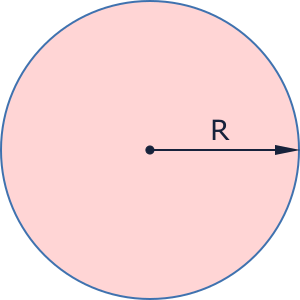

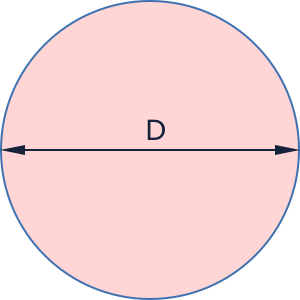

| Outside Diameter ØD | Ø 2mm to Ø 250mm |

| Thickness | up to h 100mm |

| Material | Stainless Steel 316L |

Area Result:

Sintered Stainless Steel Filter

Introducing DALON Premium Sintered Stainless Steel Filters: The Ultimate Solution for High-Purity Filtration

- In today's demanding industrial landscapes, where efficiency and reliability are paramount, our sintered stainless steel filters stand at the forefront of filtration technology. As a dedicated supplier, we are proud to offer an advanced range of sintered stainless steel filters designed to meet the rigorous standards of various sectors, including chemical processing, pharmaceuticals, food and beverage, and more.

- Crafted for Excellence:

- - Our sintered stainless steel filters are manufactured through a sophisticated process that involves compacting stainless steel powder into a mold and then sintering it at a high temperature. This process not only bonds the particles together but also creates a uniform and highly porous structure that ensures optimal filtration efficiency. The end product is a robust, durable filter capable of withstanding harsh operating conditions while providing exceptional performance.

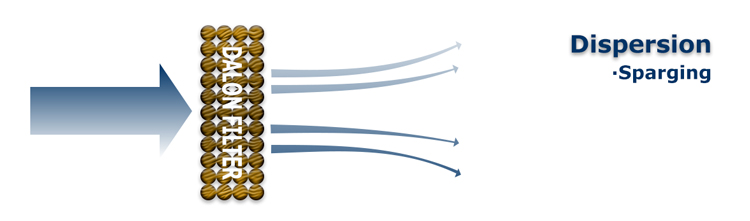

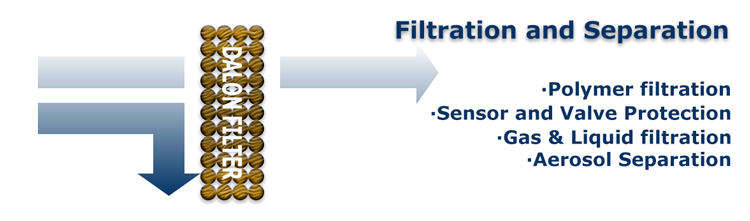

- Versatility and Performance:

- - One of the key attributes of our sintered stainless steel filter is its versatility. These filters are adept at handling a wide range of temperatures and pressures, making them suitable for a variety of applications, from gas and liquid filtration to particulate removal and even aeration. The inherent strength and corrosion resistance of stainless steel guarantee that these filters maintain integrity and performance even in the most aggressive environments.

- Customization for Specific Needs:

- Understanding that each application has unique requirements, we offer customized solutions to fit your specific needs. Our sintered stainless steel filters can be engineered in various shapes, sizes, and filtration grades to ensure that your exact specifications are met. Whether you require fine or coarse filtration, high flow rates, or specific chemical compatibility, our team is equipped to provide a tailored solution.

- Sustainable and Economical:

- Investing in our sintered stainless steel filters not only means securing a high-performance filtration solution but also choosing a sustainable and cost-effective option. These filters are designed for longevity and can be cleaned and reused multiple times, significantly reducing waste and lowering long-term operational costs.

- sintered stainless steel filters represent the pinnacle of filtration solutions, offering unmatched durability, efficiency, and adaptability. They are an invaluable asset in any application where quality and reliability are critical. Choose our sintered stainless steel filters for your filtration needs and experience the difference in performance and reliability.

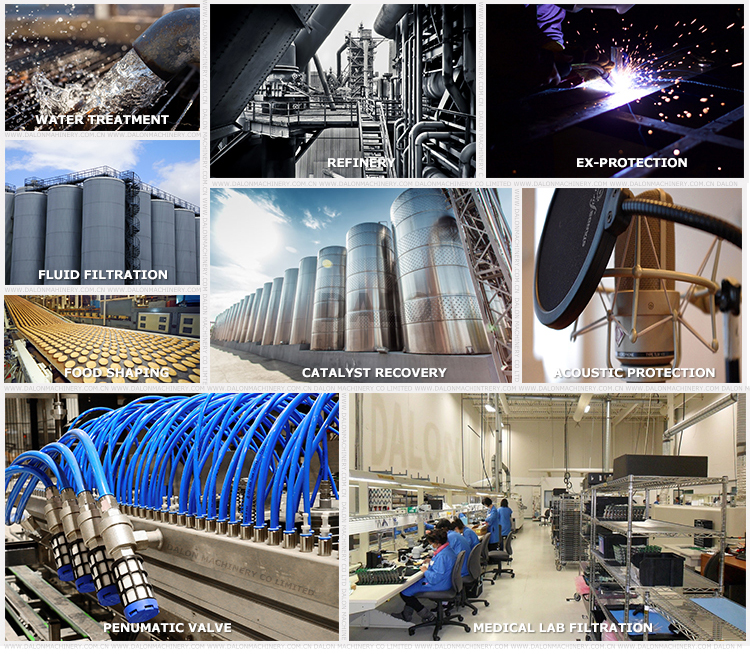

Application Examples:

| CHEMICAL INDUSTRIES | SEMICONDUCTOR |

| SCIENTIFIC INSTRUMENT | PHARMACEUTICAL |

| POLYMER FILTRATION | GAS AND LIQUID FILTRATION |

| SILENCING | SPARGING |

| FLUIDIZATION | SENSOR AND VALVE PROTECTION |

| FLOW RESTRICTION | HANDLING OF BULK MATERIAL |

- Advantages of Sintered Stainless Steel Filters

- Sintered stainless steel filters offer numerous advantages that make them suitable for these diverse applications:

- High Durability:

- - They are extremely durable and resistant to wear, capable of withstanding harsh environments, high pressures, and temperatures.

- Corrosion Resistance:

- - Stainless steel's inherent resistance to corrosion makes these filters ideal for use with aggressive chemicals and in environments where other materials would fail.

- High Filtration Efficiency:

- - The precise control over pore size distribution allows for high filtration efficiency, capturing particulates effectively while maintaining good flow rates.

- Thermal Stability

- Chemical Compatibility

- Regenerable and Cleanable

- Sintered stainless steel filters, with their robust structure and exceptional filtration capabilities, serve a broad spectrum of applications across various industries. Their ability to withstand harsh environments, coupled with excellent corrosion resistance and high temperature tolerance, makes them indispensable in many critical processes. Here's a detailed exploration of their versatile application range:

- Chemical Processing Industry:

- Pharmaceutical and Biotechnology:

- Food and Beverage Industry:

They are used to filter acids, bases, and other corrosive chemicals, preventing contamination and protecting processing equipment.

In chemical reactors, these filters are used to retain precious catalyst particles while allowing product fluids to pass through.

Essential for the sterile filtration of air, gases, and liquids in the production of pharmaceuticals, ensuring product purity and compliance with health regulations.

Used in bioreactors and fermenters for aeration and to maintain sterile conditions, preventing microbial ingress while allowing gases to flow freely.

Employed in the clarification of wines, beers, and juices, removing particulates to ensure clarity and stability of the final product.

Filters out impurities from edible oils without affecting taste or aroma.

- Water Treatment:

- Petrochemical and Gas Industries:

- Automotive Industry:

Used in the treatment of drinking water, including desalination processes, to remove particulates and ensure water quality.

Filters industrial wastewater, removing solids before discharge or recycling, thus playing a crucial role in environmental protection.

Ideal for the filtration and purification of industrial gases, hydrogen, natural gas, and air, removing contaminants to protect downstream equipment.

Used in the filtration of lubricating oils and fuels, ensuring the protection of machinery and engines.

Ensures the purity of oils and fuels in automotive engines, contributing to engine efficiency and longevity.

Filters exhaust gases, playing a role in reducing pollutants released into the environment.

- The diverse applications of sintered stainless steel filters underscore their pivotal role in modern industry, providing efficient and reliable filtration solutions that enhance product quality, protect equipment, and contribute to environmental sustainability. Their adaptability and performance under challenging conditions make them an invaluable resource across a wide range of sectors.

Contact DALON for more details