Plastic Polyethylene PE Filter Disc

Product Characteristics

| Manufacturer | DALON |

| Material | POROUS PLASTIC |

| Option | HYDROPHOBIC / HYDROPHILIC |

| Product Code | SPF |

| Pore Pitch: | from 5 µm to 80 µm |

| Diameter: | from 2 to 500 mm,and length from 2 to 1000 mm |

| Porosity: | 35 up to 45% |

| Density: | from 0.6 to 0.7 |

| Working Temp: | 110°C -MAX |

Specifications

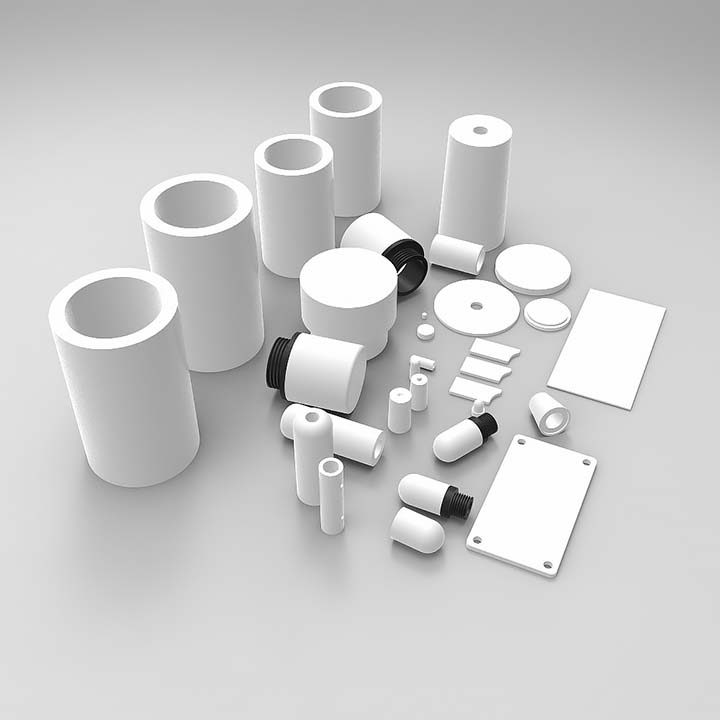

Standard Plastic Filter Disc Geometries

| Outside Diameter ØD | Ø 2mm to Ø 500mm |

| Thickness | up to h 100mm |

| Material | Polyethylene |

Area Result:

Sintered Plastic Filter Disc

Introducing Our Premier Sintered Plastic Filter Range: The Ultimate Filtration Solution

- As a leading supplier in the filtration industry, we are proud to present our top-of-the-line sintered plastic filter collection, designed to meet the most demanding filtration requirements across a wide range of applications. Our sintered plastic filters represent the pinnacle of filtration technology, offering unparalleled performance, durability, and versatility.

- Innovative Filtration Technology:

- - Our sintered plastic filters are manufactured through a cutting-edge sintering process that bonds thermoplastic particles together, creating a unique porous structure that ensures optimal filtration efficiency. This innovative method allows for precise control over pore size and distribution, resulting in filters that offer superior clarity and flow rates, while effectively removing particles and contaminants from various media.

- Versatile and Durable:

- - Crafted from high-quality thermoplastic materials, our plastic filters boast exceptional chemical resistance and can withstand harsh operating conditions, including aggressive chemicals and extreme temperatures. This makes them ideal for use in a wide array of industries, from chemical processing and water treatment to food and beverage production and pharmaceuticals.

- Eco-Friendly and Economical:

- - Our commitment to sustainability is reflected in our sintered plastic filter range. These filters are not only designed for high efficiency and minimal maintenance but are also reusable and easy to clean, significantly reducing waste and operating costs. Their long service life and energy-efficient operation make them an eco-friendly and cost-effective solution for any filtration system.

- Customizable Solutions:

- - We understand that every filtration challenge is unique, which is why we offer customizable sintered plastic filters to meet specific application requirements. Whether you need varying pore sizes, shapes, or material formulations, we are equipped to provide tailored solutions that ensure the highest level of performance and satisfaction.

- our sintered plastic filter range offers a superior, sustainable, and versatile solution for advanced filtration needs. With their unmatched quality and performance, these filters are set to revolutionize the way industries approach filtration, providing cleaner, safer, and more efficient processes. Choose our sintered plastic filters for a reliable, high-performance filtration solution that stands the test of time.

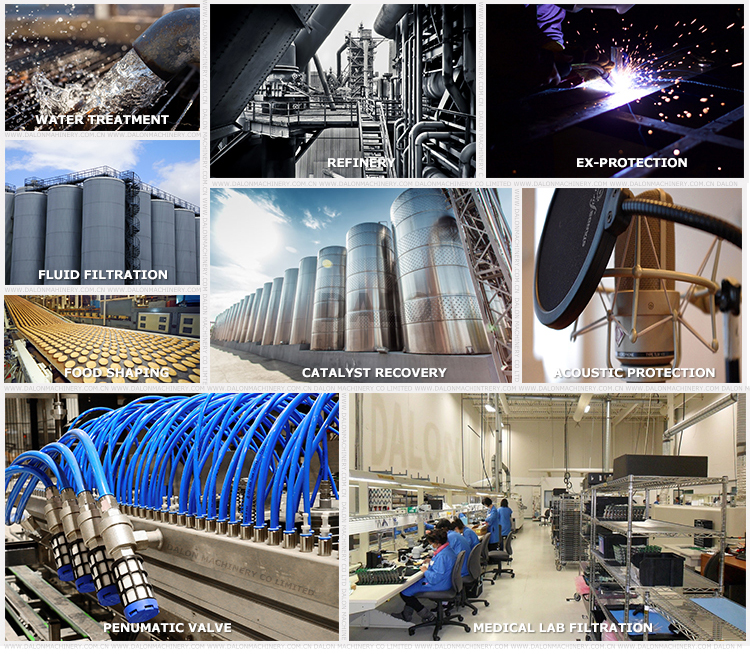

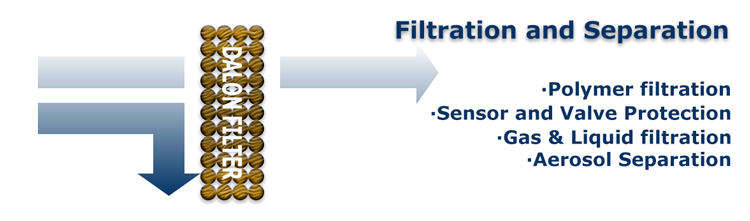

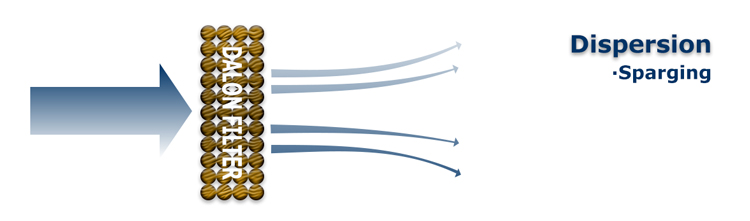

Application Examples:

| SILENCING | SPARGING |

| FLUIDIZATION | SENSOR AND VALVE PROTECTION |

| FLOW RESTRICTION | HANDLING OF BULK MATERIAL |

| CHEMICAL INDUSTRIES | SEMICONDUCTOR |

| SCIENTIFIC INSTRUMENT | PHARMACEUTICAL |

| POLYMER FILTRATION | GAS AND LIQUID FILTRATION |

- Applications Across Industries

- Sintered plastic filters have carved a niche for themselves across various industries due to their unique properties, including high porosity, excellent chemical resistance, and the ability to withstand extreme temperatures and pressures:

- Chemical Processing Industry:

- Water Treatment:

- Pneumatics and Hydraulics:

Sintered plastic filters are used to filter aggressive chemicals due to their excellent chemical resistance.

They are ideal for filtering organic solvents used in chemical synthesis and processing.

They help in purifying drinking water by removing contaminants and particulate matter.

Used in the filtration of industrial wastewater to remove harmful substances before discharge or recycling.

To remove moisture and particulate matter from compressed air lines.

Sintered plastic filters regulate fluid flow in hydraulic systems, ensuring smooth operation.

Contact DALON for more details