What is sintered stainless steel filter ?

Technical Article

Introduction

Stainless steel sintered filters are made from any metallurgical material that is produced as powder. The filters ultimate properties are influenced by the shape, size and distribution of the powder. Sintered stainless steel filter which most common materials are highly alloyed INOX/AISI316 types, but there are also nickel-based SS varieties and titanium.

The powder particles are fused to one another at temperatures well below the melting point of the material. This process gives the highly porous filter their characteristic shape and properties. After sintering, the size and position of the pores are mechanically fixed. The powder particles also form a rigid whole. This gives the filters a strength, form and stability equal to those of a metal component. Stainless steel filter are sintered porous SS parts produced from irregularly shaped SS powder, general AISI316L. They are stronger than bronze filters because of the powder's irregular shape. They are also suitable for higher temperatures.

- Stainless steel 316L

- Stainless steel 304

- Nickel-based Stainless Steel

- Titanium

The powder particles are fused to one another at temperatures well below the melting point of the material. This process gives the highly porous filter their characteristic shape and properties. After sintering, the size and position of the pores are mechanically fixed. The powder particles also form a rigid whole. This gives the filters a strength, form and stability equal to those of a metal component. Stainless steel filter are sintered porous SS parts produced from irregularly shaped SS powder, general AISI316L. They are stronger than bronze filters because of the powder's irregular shape. They are also suitable for higher temperatures.

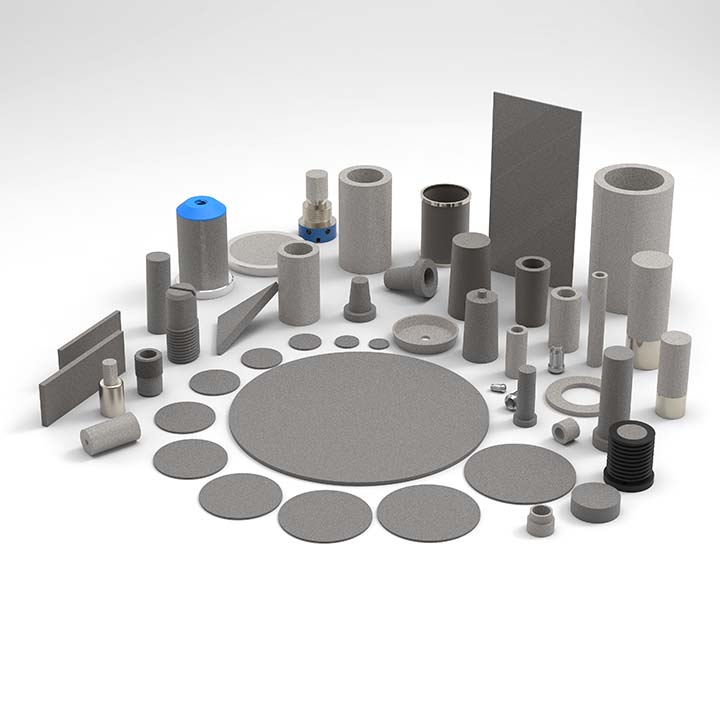

Custom Sintered Filters

The growing demand for custom sintered filters means that a major proportion of the sintered filters which we supplied are customized. DALON work closely with our customers to design and develop sintered filters that meet their exacting specifications.- Discs and Plugs: Ø d 1 mm to Ø d 250 mm , up to h 100 mm

- Rings and Hollow cylinder: Ø d 4 mm to Ø d 250 mm , up to h 1000 mm

- Plates: width up to 250 mm, h up to 50 mm & larger dimensions welded from sections

- Conical with or without flange: Ø d 4 mm to Ø d 100 mm , h 8 mm to h 250 mm

- Conical: Ø d 4 mm to Ø d 100 mm , h 5 mm to h 250 mm

- Cones with flange: Ø d 2 mm to Ø d 200 mms ,h 2 mm to h 250 mm

Application usages

All of the benefits listed above and several others make sintered porous stainless steel filter as an excellent choice for a wide range of applications, including:- Oil & Gas: The oil and gas industry can use diffusion bonded wire cloth for efficient sand control over numerous types of formation sands, as well as for multiple gravel-pack applications.

- Fluidization: Use sintered wire cloth for fluidizing bulk powders and solids under the most challenging conditions, such as extreme-temperature and high-corrosion environments.

- Power generation: Diffusion bonded wire cloth can maximize the performance of power generation filtration systems for applications such as reactor water cleanup and fuel pool cleanup. It can also help to lower the operating costs in condensate filter and polishing systems.

- General industry: General industrial applications of sintered wire cloth include catalyst recovery, steam filtration, polymer filtration, demineralizing and many others.

Enquiry to DALON

Sintered Stainless Steel Filter Elements