Sintered Iron Bushing

Product Characteristics

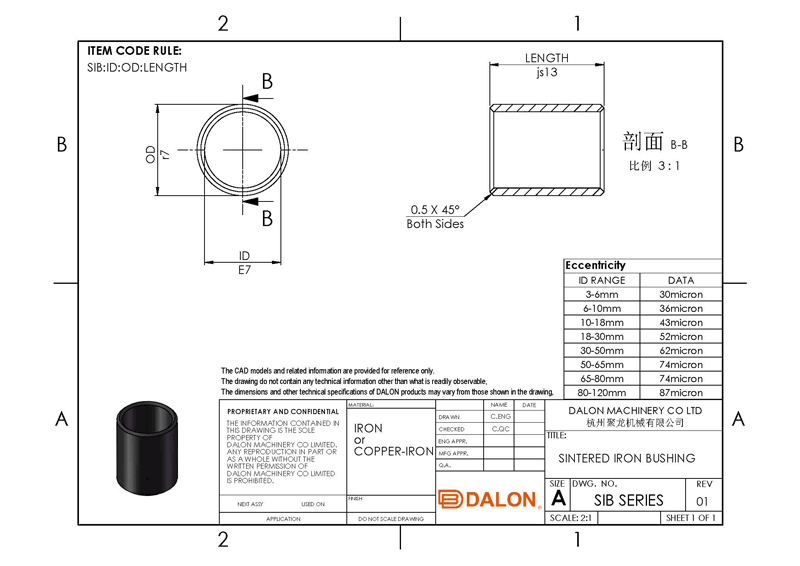

| Manufacturer | DALON |

| Material | Iron Base / SAE 863 |

| Types | Plain Type Sleeve / Flange Bushing / Spherical Ball Bushing |

| Product Code | SIB |

| Lubricating: | Embedded Lubricated SAE 30 |

| Diameter: | from 2 to 150 mm,and length from 2 to 75 mm |

| Porosity: | > 19% |

| Density: | from 6.0 to 6.8 |

| Hardness: | 35 ~ 50 HRB |

Specification Calculate

Volume

Weight

| GENERAL | UNIT | VALUE |

| Density | g/cm³ | 6.0 ~ 6.8 |

| Porosity | %(min) | >19 |

| Static Load | kg/cm² | 850 |

| Dynamic Load | kg/cm² x m/sec | 13 |

| Max Linear Speed | m/sec | 5 |

| Tensile strength at +20°C | MPa | 100 ~ 150 |

| Apparent Hardness | HB = kg/cm² | 35 |

| Friction Value | μ | 0.025 |

Sintered Iron Bushing

Discover the Robust Performance of Sintered Iron Bushing: A Supplier's Perspective

- In the dynamic world of industrial components, the sintered iron bushing stands out as a cornerstone for numerous applications, embodying durability, efficiency, and reliability. As a leading supplier of these indispensable components, we are proud to present our premium range of oil-impregnated sintered iron bushings, crafted to exceed the expectations of even the most demanding industrial environments.

- Engineered for Excellence:

- - Our sintered iron bushing products are manufactured using a refined powder metallurgy process. This process involves compressing iron powder into a desired shape and then heating it below its melting point to bond the particles. The resulting structure is not only incredibly dense and uniform but also inherently strong. The pores created during the sintering process are then vacuum-impregnated with lubricating oil, ensuring that each bushing offers self-lubricating properties. This design innovation means our bushings continuously provide lubrication between the bushing and its mating components, reducing wear and extending the service life of both the bushing and the machinery.

- Versatile and Reliable:

- - Sintered iron bushings are renowned for their high compressive strength, making them particularly suitable for applications subjected to high loads and stresses. This makes them an ideal choice for heavy machinery, automotive applications, agricultural equipment, and industrial motors, where reliability and endurance are paramount. The oil impregnation ensures a low coefficient of friction, minimizing operational noise and enhancing performance efficiency.

- Customization and Compatibility:

- - Understanding the diverse needs of industries, we offer sintered iron bushings in a wide range of sizes and shapes, with customization options available to meet specific application requirements. Our bushings are compatible with a broad spectrum of environments, including those with fluctuating temperatures and varying degrees of exposure to corrosive substances.

- Sustainable and Cost-Effective:

- - Our commitment to sustainability is reflected in the production process of our sintered iron bushings. The efficient use of materials and the long-lasting nature of our products contribute to a lower environmental impact and reduced need for replacement parts. Additionally, the self-lubricating feature of our bushings leads to lower maintenance costs, making them a cost-effective solution for many industrial applications.

- DALON sintered iron bushing range is designed to offer superior performance, durability, and reliability, catering to the rigorous demands of modern industry. With their robust construction, self-lubricating properties, and versatility, these bushings are poised to enhance the efficiency and longevity of your machinery, ensuring smooth and reliable operation across various applications.

Application Examples:

- DALON Sintered Bushing Advantage:

- Sintered iron bushings offer a compelling suite of advantages that make them indispensable in various industrial applications. Here's a concise overview of their key benefits:

- Self-Lubricating:

- - The oil-impregnated nature of sintered iron bushings provides a self-lubricating feature, significantly reducing maintenance requirements and enhancing operational efficiency by minimizing friction and wear.

- High Strength and Durability:

- - Sintered iron bushings are known for their exceptional strength and durability. The sintering process results in a product that can withstand high loads and stresses, making them ideal for heavy-duty applications.

- Cost-Effective:

- - These bushings are economically advantageous due to their long service life and the reduced need for maintenance and lubrication, which can lead to lower operational costs over time.

- Sintered iron bushings are integral components in a wide range of applications due to their durability, self-lubricating properties, and high load-bearing capacity. Their use spans various industries, highlighting their versatility and essential role in enhancing machinery performance and longevity. Here’s a detailed look into the applications of sintered iron bushings:

They are used within gearboxes for smooth gear shifting and in transmissions due to their ability to withstand

high rotational speeds and varying temperatures.

Sintered Iron bushings find applications in suspension systems, where their durability and shock absorption

qualities are valuable.

Found in hydraulic pumps and motors, where they withstand high pressures and facilitate smooth operation.

Utilized in rollers and pulleys to support heavy loads and reduce friction in material handling equipment.

Sintered Iron bushings are commonly used in electric motors for fans, air conditioners, and washing machines, providing longevity and noise reduction.

Essential in domestic and industrial pumps and compressors for water, air, and other fluids.

They are employed in wind turbine mechanisms, where their resistance to wear and self-lubricating properties ensure efficient and long-term operation.

In agricultural machinery, these bushings reduce the wear and tear on moving parts, extending the equipment's

service life and reliability.

Sintered Iron bushings are used in boat and ship propulsion systems, benefiting from their corrosion

resistance and durability in wet environments.

DALON sintered Iron bushing provide smooth operation and support for moving parts within printers and

photocopiers, where precision and reliability are essential.

In fitness equipment, such as weight machines and stationary bikes, these bushings ensure smooth operation and

resistance to sweat and moisture.

- In summary, sintered iron bushings are a robust, maintenance-friendly, and cost-effective solution for applications requiring durable and reliable performance under high loads and in challenging environments.