The Strategic Advantage of Sintered Stainless Steel Filtration in Extreme Industrial Environments

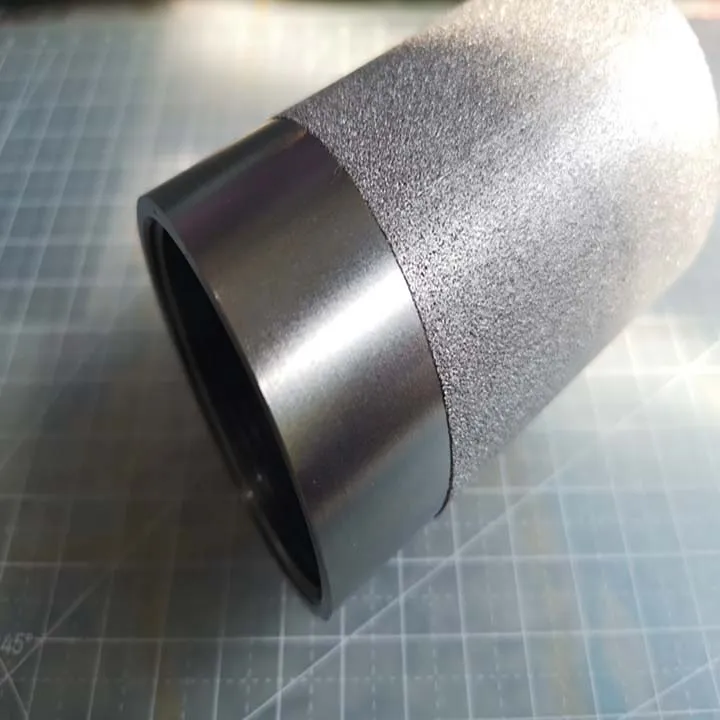

In modern industrial processing, the integrity of filtration media is not merely a technical detail; it is a cornerstone of operational resilience and...