Casquillo de Hierro Sinterizado en Calidad Premium

| Fabricante | DALON |

| Material | Base de hierro / SAE 863 |

| Tipo | SLEEVE BUSHING |

| Temperatura de Trabajo в„?/td> | from -20В°C to +120В°C |

| CГіdigo de Producto | BEF061010 |

| Densidad (g/cmВі) | from 6.0 to 6.8 |

| CГіdigo HS | 84839000 |

| Dureza | 35 ~ 50 HRB |

| Carga EstГЎtica (Mpa) | 850 kg/cmВІ |

| MГЎx. Velocidad (m/s) | 5 m/s |

| MГЎx PV (seco) | 1.0 вҖ“ 1.5 MPaВ·m/s |

| I.D.(d) | 6 |

| I.D. (d1) | |

| A.D. (D) | 10 |

| A.D. (D1) | |

| Longitud (L) | 10 |

| DiГЎmetro del Flanco (fd) | |

| Espesor del Flanco (fl) | |

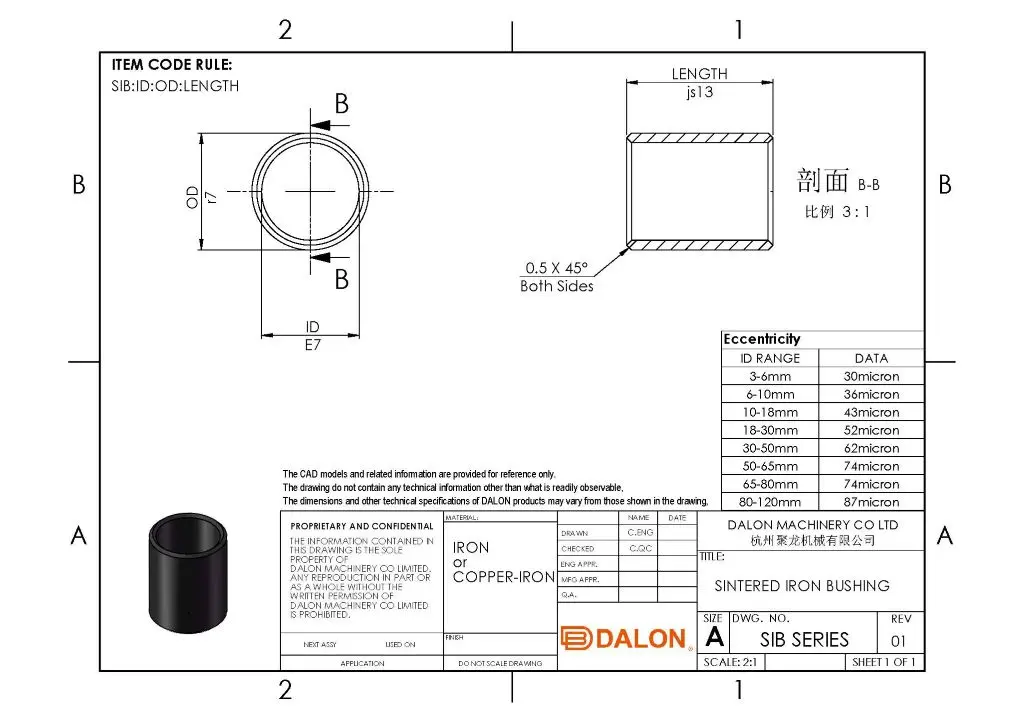

| Tolerancia General | E7 r7 js13 |

| Peso(Ref.)/Gramo | 3.50 |

| Cantidad MГӯnima de Pedido | 40KGS |

Bujes de hierro grafitado – Bujes de hierro sinterizado 06×10×10

El buje de hierro grafitado 06×10×10 de Dalon es un componente de hierro sinterizado de precisión diseñado para soporte rotacional en sistemas mecánicos compactos. Fabricado mediante pulvimetalurgia, este casquillo presenta infusión de grafito para un rendimiento autolubricante en condiciones secas o de lubricación marginal. Con unas dimensiones de 6 mm de diámetro interior, 10 mm de diámetro exterior y 10 mm de longitud, encaja perfectamente en alojamientos reducidos como cajas de engranajes, herramientas, bombas y motores pequeños.

Su contenido en grafito permite un mantenimiento mínimo a la vez que resiste el desgaste y la deformación, por lo que es ideal para aplicaciones en las que son esenciales un movimiento constante de baja fricción y una larga vida útil.

Características principales

Dimensiones: 6 mm ID × 10 mm OD × 10 mm de longitud

Material: Hierro sinterizado infundido con grafito

Autolubricante con lubricante sólido incrustado

Resistente a la corrosión y al desgaste para un uso prolongado

Diseñado para funcionamiento en seco o lubricación ligera

Alternativa rentable a los cojinetes de bronce

Aplicaciones

Herramientas eléctricas y bujes de motor

Ejes de bombas pequeñas y unidades de accionamiento

Maquinaria agrícola y de jardinería

Equipos rotativos en electrodomésticos

Herramientas eléctricas y motores de hobby

Por qué elegir DALON

DALON es un fabricante con certificación ISO 9001:2015 especializado en cojinetes y casquillos sinterizados. Ofrecemos:

Producción personalizada basada en sus dimensiones y tolerancias

Asistencia en el diseño para la fabricación y optimización de materiales

Soporte OEM con especificaciones tanto métricas como imperiales

Cadena de suministro fiable con precios estables y control de calidad

Entrega de utillaje estándar en ~30 días; moldes y piezas a medida en 35–40 días incluyendo utillaje

Bajo MOQ para casquillos personalizados – póngase en contacto con nosotros para requisitos específicos de volumen

P1: ¿Para qué se utiliza un casquillo de hierro grafitado?

Los casquillos de hierro grafitado se utilizan comúnmente en conjuntos giratorios compactos para reducir la fricción y el desgaste sin lubricación adicional, especialmente en herramientas, bombas y motores eléctricos.

Los casquillos de hierro grafitado se utilizan comúnmente en conjuntos giratorios compactos para reducir la fricción y el desgaste sin lubricación adicional, especialmente en herramientas, bombas y motores eléctricos

P2: ¿Este casquillo es autolubricante?

Sí. El hierro sinterizado está impregnado de grafito que actúa como lubricante seco, lo que lo hace ideal para aplicaciones con acceso limitado a grasa o aceite.

P2: ¿Este casquillo es autolubricante?

Sí

Q3: ¿Cuáles son las ventajas del grafito sobre el bronce impregnado de aceite?

Los casquillos de grafito rinden mejor a temperaturas más altas y son más resistentes a la desecación. También son más económicos en algunos sistemas de servicio pesado o de uso intermitente.

Q4: ¿Puedo pedir un tamaño personalizado?

Por supuesto. DALON admite la personalización completa, incluidos el diámetro exterior/interior, la longitud, los tipos de brida y las mezclas de materiales. Póngase en contacto con nuestro equipo para una consulta de diseño.

Q5: ¿Cuál es el plazo de entrega estándar para los casquillos personalizados?

El plazo de entrega típico para los casquillos personalizados (incluido el diseño del molde y la producción) es de 35–40 días. Para herramientas en stock o existentes, el plazo de entrega es de unos 30 días.

Q6: ¿Cuál es la cantidad mínima de pedido para un casquillo a medida?

Depende del tamaño de la pieza y de la aplicación. Por favor, póngase en contacto con DALON con sus especificaciones y le aconsejaremos el MOQ en consecuencia.

P7: ¿Cuál es la diferencia entre los casquillos de hierro grafitado y los de bronce con baño de aceite?

Aunque ambos son autolubricantes, el hierro grafitado es más adecuado para entornos de alta carga o sucios. El bronce es mejor para la rotación continua y un funcionamiento más silencioso.

Q8: ¿Pueden utilizarse estos bujes en exteriores o en entornos difíciles?

Sí. Los casquillos de hierro grafitado son resistentes al polvo, la humedad moderada y las condiciones abrasivas, aunque para aplicaciones marinas o de alta corrosión, los casquillos revestidos o de bronce pueden ser más adecuados.

Sí

La versatilidad de los CASQUILLO DE HIERRO SINTERIZADO 06X10X10 los hace ideales para numerosas aplicaciones, incluyendo:

Los CASQUILLO DE HIERRO SINTERIZADO 06X10X10 estГЎn diseГұados para aplicaciones pesadas donde capacidad de carga superior y durabilidad son esenciales. Ofrecen resistencia al desgaste excepcional, altas capacidades de carga y larga vida Гәtil, haciГ©ndolos la opciГіn ideal para aplicaciones industriales exigentes. Experimente la resistencia y confiabilidad de los CASQUILLO DE HIERRO SINTERIZADO 06X10X10, diseГұados para cumplir con los rigurosos requisitos de construcciГіn de maquinaria pesada y equipamiento industrial.

Nuestro equipo profesional estГЎ listo para ayudarle con su solicitud para este casquillo de hierro con grafito de 6 mm - Tipo autolubricante.

ContactoTodos nuestros productos se fabrican segГәn estГЎndares ISO 9001.

Ver CertificadosOfrecemos servicios de diseГұo gratuitos y fabricaciГіn a medida para sus requisitos especГӯficos.

Ofrecemos envГӯo mundial para todos nuestros productos con tiempos de entrega confiables.