Bague fer frittĂŠe de qualitĂŠ premium

| Fabricant | DALON |

| MatĂŠriau | Iron Base / SAE 863 |

| Type | SLEEVE BUSHING |

| TempĂŠrature de fonctionnement â?/td> | from -20°C to +120°C |

| Code produit | BEF061010 |

| DensitĂŠ (g/cmÂł) | from 6.0 to 6.8 |

| Code HS | 84839000 |

| DuretĂŠ | 35 ~ 50 HRB |

| Charge statique (Mpa) | 850 kg/cm² |

| Vitesse max. (m/s) | 5 m/s |

| Max PV (sec) | 1.0 â 1.5 MPa¡m/s |

| D.I.(d) | 6 |

| D.I. (d1) | |

| D.E. (D) | 10 |

| D.E. (D1) | |

| Longueur (L) | 10 |

| Diamètre bride (fd) | |

| Ăpaisseur bride (fl) | |

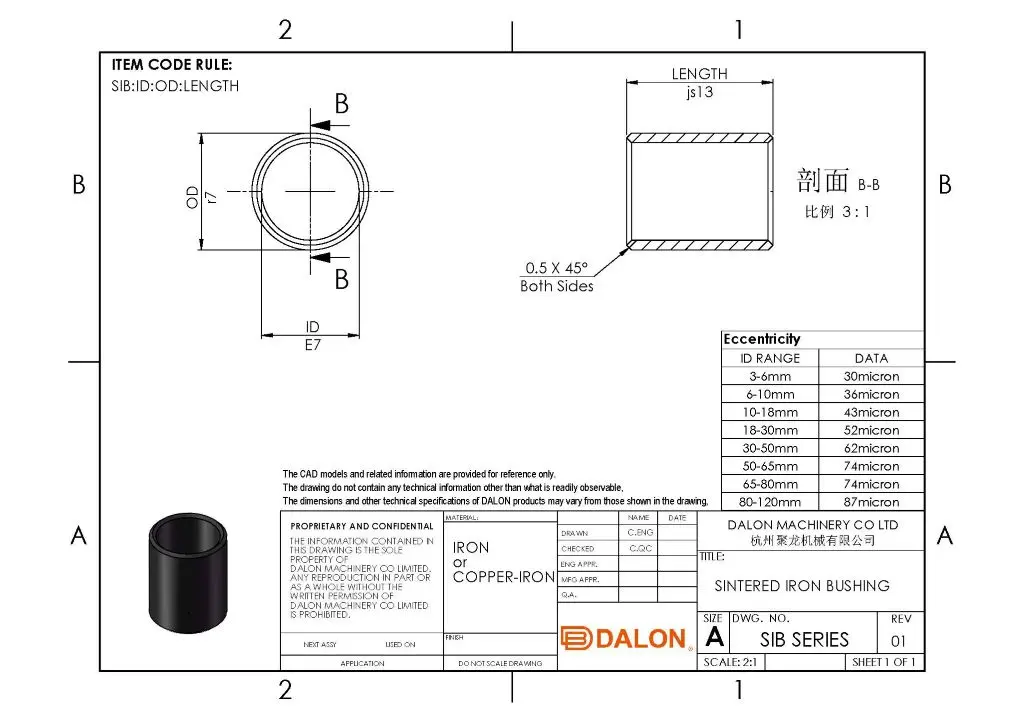

| TolĂŠrance gĂŠnĂŠrale | E7 r7 js13 |

| Poids(RĂŠf.)/Gramme | 3.50 |

| QuantitĂŠ minimum de commande | 40KGS |

La bague en fonte graphitée DALON 06×10×10 est un composant de précision en fer fritté conçu pour le support en rotation dans des systèmes mécaniques compacts. Fabriquée selon un procédé de métallurgie des poudres, cette bague est infusée de graphite pour garantir une lubrification autonome en fonctionnement à sec ou faiblement lubrifié.

Avec un diamètre intérieur de 6 mm, un diamètre extérieur de 10 mm et une longueur de 10 mm, elle s’intègre parfaitement dans les logements étroits tels que les réducteurs, outils, pompes et petits moteurs. Son graphite intégré assure un entretien minimal tout en réduisant l’usure, ce qui la rend idéale pour les applications nécessitant un mouvement à faible friction et une longue durée de vie.

Dimensions : 6 mm (DI) × 10 mm (DE) × 10 mm (longueur)

Matériau : Fer fritté imprégné de graphite

Auto-lubrifiant grâce au lubrifiant solide intégré

Résistance à la corrosion et à l’usure pour une utilisation prolongée

Fonctionnement à sec ou lubrification minimale

Alternative économique aux bagues en bronze

Bagues de moteurs et d’outils électroportatifs

Arbres de petites pompes et unités d’entraînement

Machines agricoles et de jardinage

Équipements rotatifs dans les appareils ménagers

Moteurs électriques miniatures et de loisirs

DALON est un fabricant certifié ISO 9001:2015, spécialisé dans les paliers et bagues frittés. Nous proposons :

Production sur mesure selon vos dimensions et tolérances

Assistance à la conception et optimisation des matériaux

Support OEM en dimensions métriques et impériales

Chaîne d’approvisionnement fiable avec contrôle qualité rigoureux

Délais : 30 jours pour outils standards, 35–40 jours pour outillage + production

MOQ réduit pour les pièces personnalisées – contactez-nous pour vos besoins

Q1 : À quoi sert une bague en fonte graphitée ?

Elle réduit la friction et l’usure dans les assemblages rotatifs compacts, sans nécessiter de graissage, notamment dans les outils, pompes et moteurs.

Q2 : Cette bague est-elle auto-lubrifiante ?

Oui. Le graphite intégré agit comme lubrifiant sec, idéal pour les zones difficiles d’accès sans graissage régulier.

Q3 : Quels sont les avantages du graphite par rapport au bronze imprégné d’huile ?

Le graphite supporte mieux les hautes températures, ne se dessèche pas, et est plus économique dans les environnements de forte charge ou d’utilisation intermittente.

Q4 : Peut-on commander une taille personnalisée ?

Absolument. DALON propose une personnalisation complète : diamètre intérieur/extérieur, longueur, type de bride, et composition du matériau.

Q5 : Quel est le délai standard pour une bague personnalisée ?

Comptez 35–40 jours pour une pièce avec nouveau moule, ou environ 30 jours si l’outillage existe déjà.

Q6 : Quelle est la quantité minimale de commande (MOQ) ?

Cela dépend des dimensions et de l’application. Contactez DALON avec vos spécifications pour un devis personnalisé.

Q7 : Quelle est la différence entre une bague en fonte graphitée et une bague en bronze huilé ?

La fonte graphitée est plus adaptée aux environnements sales ou à forte charge. Le bronze huilé est préférable pour une rotation continue et silencieuse.

Q8 : Cette bague convient-elle aux environnements extérieurs ou difficiles ?

Oui. Elle résiste à la poussière, à l’humidité modérée et à l’abrasion. Pour les environnements marins ou très corrosifs, préférez une bague avec revêtement ou en bronze.

La polyvalence des DOUILLE EN FER FRITTĂ 06X10X10 les rend idĂŠales pour de nombreuses applications, notamment :

Les DOUILLE EN FER FRITTà 06X10X10 sont conçues pour les applications lourdes oÚ une capacitÊ de charge supÊrieure et une durabilitÊ sont essentielles. Elles offrent une rÊsistance à l'usure exceptionnelle, des capacitÊs de charge ÊlevÊes et une longue durÊe de vie, ce qui en fait le choix idÊal pour les applications industrielles exigeantes. DÊcouvrez la force et la fiabilitÊ des DOUILLE EN FER FRITTà 06X10X10, conçues pour rÊpondre aux exigences rigoureuses des Êquipements lourds et industriels.

Notre ĂŠquipe professionnelle est prĂŞte Ă vous aider avec votre demande pour ce 6 mm Douille en fer enrobĂŠe de graphite - Type autolubrifiant.

ContactTous nos produits sont fabriquĂŠs selon les normes ISO 9001.

Voir les certificatsNous offrons des services de conception gratuits et une fabrication sur mesure pour vos besoins spĂŠcifiques.

Nous offrons l'expĂŠdition mondiale pour tous nos produits avec des dĂŠlais de livraison fiables.